Phone: (+27) 11 664-6370/6377/6099/6362

Email: beadsint@icon.co.za

|

BEADS INTERNATIONAL |

| "Welcome to our world of grinding media" |

A high-quality grinding medium, CENOBEAD™ CZC has high density, making it very efficient for grinding materials having high viscosity.

Its grinding efficiency is similar to that of CZY, but its price is low, which means that it can be favorably applied to the paint and ink industry.

Its excellence is exemplified by the fact that CZC has been applied to the grinding CaCO3 for high viscosity paper coating. Through this, CZC has been proved to be a global standard grinding medium. It is generally known that it is difficult to apply a small high-density bead to a vertical-type grinding machine with a large capacity, but by applying a small high-density CZC to a vertical-type grinding machine, remarkably greater productivity can be achieved than would be possible through the use of alumina or zirconium silicate bead.

| Chemical Composition and Physical Properties | |||

| Composition | Zr02 | 75 ~ 85 | |

CeO3 |

15 ~ 25 | ||

| Specific Density | ≥ 6.20 | ||

| Bulk Density |

|

||

| Hardness | ≥ 1200 | ||

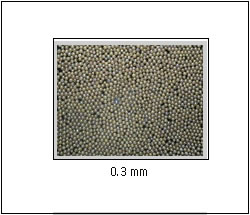

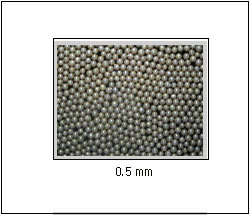

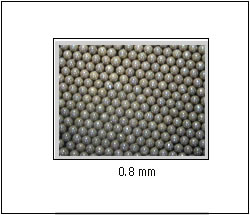

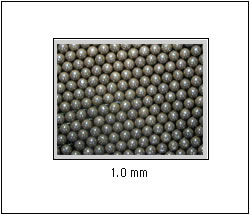

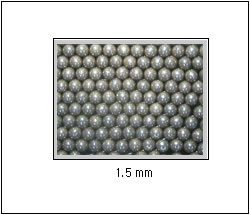

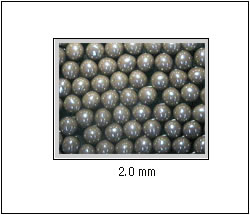

| Standard Size | 0.30, 0.50, 0.70, 0.80, 1.00, 1.20, 1.50, 2.00, 2.20, 2.50, 2.70 | ||

| Sphericity | ≥ 92 | ||

| Packing | 25Kgs | ||

| Typical Properties of Zirconox Micro Milling Beads | |

Chemical composition |

ZrO2 80%, CeO2 20% |

Density |

> 6.1 gm/cc |

Packing density/Bulk Volume |

3.60 - 3.70 Kg's/ltr. |

Hardness on Moh's scale |

9 |

Hardness (HV10) |

1100 - 1150 |

Crushing strength on 2mm dia grain |

> 250 Kg |

Water absorption |

Nil |

Porosity |

Gas Tight |

Grain Sphericity |

> 0.8 |

Colour |

Golden Brown |

Surface finish |

Glossy satin smooth |

We reserve the right to modify the product specifications. Values quoted are typical results before sizing and packing. Beads are available in the following sizes: 0.4/0.7mm, 0.7/1.2mm, 1.2/1.7mm, 1.7/2.4mm, 2.4/2.8mm, 2.8/3.3mm.

We can also offer on request custom size or narrow fraction range size beads other than our standard sizes, if found feasible to produce them.